The principles of cleaning involve a combination of thermal, kinetic and chemical energy. The cleaning processes are always a combination of these factors. The key point to highlight is that all equipment - including drainage - in food processing plants should have hygienic design, which is easy to clean and disinfect. Otherwise, the cleaning process is time and energy consuming and is not cost effective. All surfaces of ACO Stainless Steel Drainage are hygienically designed - no sharp corners, edges, dead spaces or crevices. ACO Drainage is easily accessible for cleaning and visual inspection.

The effectiveness of drainage cleaning depends on a number of factors:

- Soil type and properties

- Material, design and surfaces

- Water quality

- Cleaning chemicals

- Cleaning procedure

- Cleaning parameters: temperature, time, flow velocity and concentration of chemicals

__________________________________________________________________________________________

There are two different types of surface to be cleaned:

Product contact surface:

All equipment that intentionally or unintentionally (e.g. due to splashing) comes in contact with final product from which product or condensate may drain, drop or be drawn.

Non product contact surface:

All other exposed surfaces, including surfaces associated with equipment, such as support structures, control panels, and external surfaces. It also includes surfaces related to the manufacturing environment, such as floors, walls and drain channels.

__________________________________________________________________________________________

We also differentiate the cleaning process between whether it is applied dry or wet.

Dry Cleaning:

Dry cleaning is essentially a mechanical removal of soils using sweeping, brushing, wiping and vacuuming. Environments typically to be cleaned by dry methods include plants which are producing flour, cocoa, dry milk, products, dry soups and dry infant formulas.

Wet Cleaning:

Wet Cleaning involves application of fluids (usually water based) to achieve the desired cleaning result. This can be applied to Open Plant Cleaning (OPC): surfaces to be cleaned have to be accessible to fluids. In addition, some components may be physically removed from the production area and cleaned separately - Cleaning out of place (COP). Drainage systems require wet cleaning.

__________________________________________________________________________________________

The last is a distinction between whether the cleaning process is done manually or automatically.

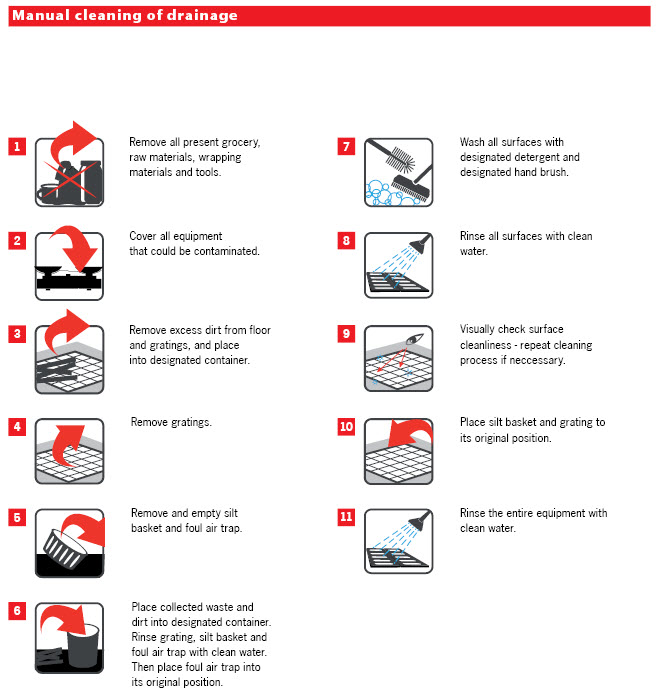

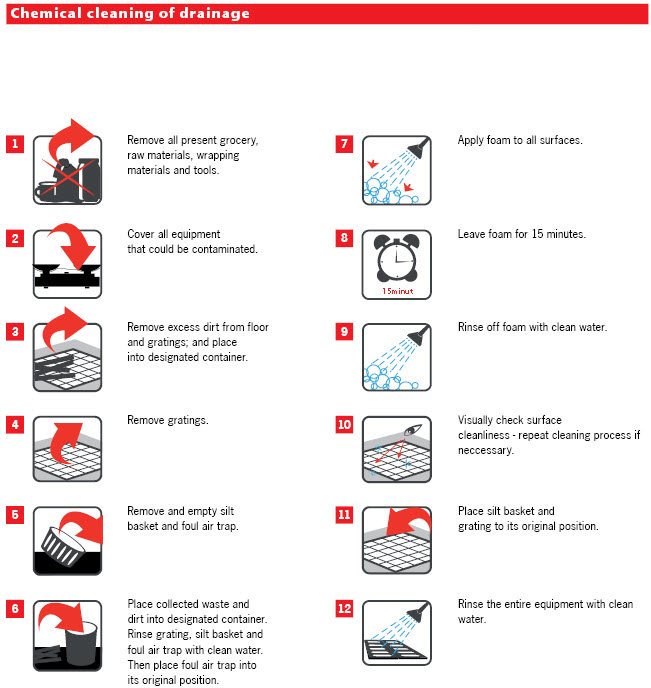

Manual Cleaning:

Manual cleaning is generally considered labor intensive and often very expensive. The manual tools should be hygienic - resistant to applied chemicals and suitable for a specific operation. On top of it, that operators should be properly trained to be able to perform cleaning as expected to achieve clean surfaces. ACO Drainage has all elements of hygienic design that makes cleaning of ACO drainage much easier and faster when compared to competitive products.

Automatic Cleaning:

Utensils and dismantled parts of equipment are cleaned and disinfected automatically in industrial washing machines, tray or tunnel washers (automatic COP). CIP is also defined as a automatic cleaning system.

These instructions are for guidance only. Always follow manufacturer instructions.

All procedures have to be verified and adjusted to the application specifics.

| Frequency | Procedure | Physical agents | Chemical agents | Examples of chemical cleaning agents suitable for ACO stainless steel drainage |

|---|---|---|---|---|

| Daily | Removal of organic deposits (fats, proteins, saccharides and polysaccharides) | - Steam | - Caustics (sodium hydroxide, potassium) - Detergents / surfactants | Standard chemical agents used for floor cleaning should be sufficient (should be validated) Oxofoam, Endorochlor (Diversey) |

| Weekly | Removal of inorganic deposits that could promote very resistant biofilms | Mechanical abrasive methods - polishing | - Nitric acid for stainless steel passivation where chlorine attack could be expected - Inorganic acids (phosphoric acid) - Weak organic acids - Inorganic acids (phosphoric acid) | - Aciforam (Diversey) - DeAcigel (Diversey) - Super Dilac (Diversey) |

| Note | Removal of rinse water residue | Removal of excess water with a squeegee | Alcohols (isopropylalcohol, ethanol) | Chlorine tablets (Suma Tab D4 by Diversey) are often added to the water in foul trap in microbial sensitive production areas |