ACO, Inc. introduced the concept of modular trench drains to North America over 40 years ago. Today, ACO in North America is a multi-site manufacturing and sales operation using a variety of materials for its extensive range of drainage products for all aspects of building and construction.

ACO USA is a sales and marketing company with its own strong manufacturing bases. ACO USA supports its business with all the elements of a diverse company. In addition to modern manufacturing facilities for its product lines, ACO offers field support for all aspects of the business - from specification advice to installation expertise. ACO is the recognized CES provider for architeths and engineers on surface drainage education.

As a market leader, ACO USA is constantly innovating to bring new products to the market. ACO has a fully established R&D department responsible for continuous development, quality, and testing to ensure ACO products continue to lead the market.

During the 1970's, ACO introduced modular, polymer concrete trench drains to the US market. Today, ACO manufactures a range of drainage and landscape products from polymer concrete, stainless steel, mild steel, cast iron, fiberglass, and molded plastics. These diverse material types are used to produce components for all applications - commercial and residential construction, as well as electromechanical engineering and environmental protection.

The ACO Group

ACO USA is part of the ACO Group, a multinational company specializing in products for the construction and building industries.

The ACO Group employs more than 5,000 people worldwide in 40 countries, with production facilities in North America, Europe, China, and Australia, specializing in the manufacture of polymer concrete, cast iron foundry, and plastic extrusion. These resources, supplemented with a worldwide network of agents, make ACO products available in every corner of the world.

The ACO Group is dedicated to achieving the highest possible standards of quality throughout the organization, many companies have either been assessed to or operate an ISO 9002 system, the internationally recognized standard for quality. For full details go to www.aco.com.

Join us at tradeshows to speak with our experts and see our latest products.

Up next:

DHPA (Decorative Plumbing & Hardware Association) Annual Conference - Seattle, WA, November 7-10, 2019

KBIS (Kitchen & Bath Industry Show) - Las Vegas, NV January 21-23, 2020

HDexpo (Hospitality Design Expo) - Las Vegas, NV May 5-7, 2020

AIA Architecture Expo (American Institute of Architects)- Los Angeles, CA, May 14-16, 2020

ASPE (The American Society of Plumbing Engineers) Convention & Expo - New Orleans, LA, September 11-16, 2020

ACO. creating the future of drainage

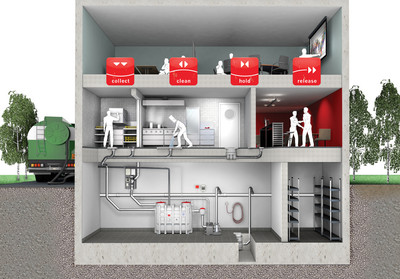

In a food processing and commercial kitchen environment, hot water, grease, and organic waste must be counteracted by more complex and sophisticated drainage concepts. ACO achieves this with intelligent system solutions which optimize food safety of employees and the protection of water. Every ACO product within the ACO system chain safely controls water as it passes along the chain to ensure it can be hygienically, economically, and ecologically handled in a visible way.

System Chain Overview and Benefits

ACO provides solutions which optimize food safety, employee's health and safety, and water protection. Every ACO product safely controls the water to ensure it can be hygienically, economically, and ecologically managed in a viable way.

Food Safety

- ACO Stainless Drainage fulfills hygienic requirements to prevent harmful bacteria contamination. We apply relevant hygienic design principles reserved for food contact surfaces as recommended by EHEDG and NSF/ANSI.

- Our product design ensures minimal buildup of food particles and debris as well as a safe connection with the surrounding floor to minimize any opportunity for bacteria to grow throughout the drain system.

- Slope function and hygienically designed products ensure our system is fully drainable, eliminating the stagnant odor of waste water.

Cost Control

- ACO Drainage Systemscan be easily maintained reducing associated cleaning vosts, thanks to their functional design and cleaning recommendations which have developed in partnership with premium cleaning agent suppliers.

- ACO's advanced manufacturing technologies ensure durability and our special surface treatment guaranteesn corrosion resistance. Our systems perform effectively at all times and keep business disruption to a minimum.

- We provide expertise in drainage system planning, correct installation and creating a safe connection with the surrounding floor to avoid unneccessary costs.

Health & Safety

- Slip resistant grating is used in high risk areas that require heavy water usage providing additional safety.

- Each component of the drainage system is easy to remove and clean, and there are no sharp edges for optimum employee safety.

Material

Stainless Steel

Stainless steel is the name given to a wide range of steels which have the characteristics of greatly enhanced corrosion resistance over conventional mild and low alloy steels. The enhanced corrosion resistance of stainless steel essentially comes from the addition of at least 11% chromium, however, most stainless steels commonly used contain around 18% chromium. Other significant alloying elements include nickel and for superior corrosion resistant properties, molybdenum.

Unique Advantages of Stainless Steel

- High corrosion resistance

- Non-porous, easy to clean and disinfect

- Aesthetically pleasing

- Resistant to extreme temperatures and thermal shock

- Cooefficient of linear expansion similar to that of concrete

- 100% recyclable material

ACO Stainless products are manufactured from austenitic stainless steel, grades AISI 304 or 316L and is ideal for applications including food processing, leisure, dairy, brewing, pharmaceutical, chemical and petrochemical industries.

Surface Treatment

The process cutting, forming, and welding of stainless steel will introduce impurities into the surface of the material and unless the appropriate action is taken, the material will begin to corrode and ultimately fail in service. Therefore, after fabrication, it is vital that stainless steel be treated with the correct surface treatment to ensure it is fully corrosion resistant. By applying pickle passication as the primary surface treatment, the corrosion resistance of stainless steel can be fully restored to its original state, ensuring long and reliable life performance together with the required aesthetic appearance.

Finishes Used by ACO

Pickle Passivation (acid treatment)

All ACO drainage is pickle passivated by immersing products in a series of acid baths. This is a fundamental requirement for removing iron embedded particulates introduced in the fabrication process and also for restoring the chromium depleted regions generated by the welding process. ACO has some of the largest and most advanced pickle passivation installations ensuring optimum corrosion resistance of our products.

Electropolishing (electrochemical process)

After pickle passication, some products are then immersed in an electrolytic fluid in which the products become the anode of a direct current electrical circuit. This process is characterized by a selective attack of the surface of the components whereby upstanding roughness is preferentially dissolved and will yield a progressively smoother, brighter surface. All ACO hygienic trench drain grates are electro-polished.

Brushing (mechanical process)

ACO trench drains have aesthetically pleasing brushed upper edges.

Application

The layout of the drainage system has an impact on future operational effectiveness and costs. This guide offers a range of basic areas which needs to be considered when specifying a drainage system. To specify an appropriate drainage system for a particular application, the zone of operation and amount and frequency of water should be considered.

| Production process/Cleaning Process | High Risk Food Safety Zones | Medium or Low Risk Food Safety Zones | Zones Without Direct Risk for Food Safety |

|---|---|---|---|

| Wet production process/Wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast grates High capacity - high flow rate Slip resistance - high requirement | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow High capacity - high flow rate Slip resistance - high requirement | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. High capacity - high flow rate Slip resistance - high requirement |

| Dry production process/ Wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast iron grates High flow rate Slip resistance - medium requirement | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow High flow rate Slip resistance - medium requirement | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. High flow rate Slip resistance - medium requirement |

| Dry production process/ Controlled wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast grates Medium to low flow rate Slip resistance recommended | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow Medium to low flow rate Slip resistance recommended | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. Medium to low flow rate Slip resistance recommended |

Type of Drainage

Based on the application, the type of drainage should be selected according to the layout of the operational space and processing technology employed.

Material Resistance

The chemical mixture of the waste water from the process and/or from the cleaning, as well as temperature of the final mixture influences the material resistance of the drainage system.

ACO drainage is manufactured from astenitic stainless steel; grades 304 or 316L according to AISI and is ideal for applications within food processing, dairy, brewery, commercial kitchen, pharmaceutical, chemical, petrochemical, and leisure industries.

Besides stainless steel, drainage products also contain sealing materials:

ACO Floor Drains - All seals are made of NBR (acryl nitrile-butadiene rubber)

ACO Trench and Slot Drains - Flange connection seals are made of NBR (acryl nitrile-butadiene rubber)

ACO Modular Trench and Slot Drains - Flange connection seals are made of NBR (nitrile-butadiene rubber)

ACO, Inc. introduced the concept of modular trench drains to North America over 40 years ago. Today, ACO in North America is a multi-site manufacturing and sales operation using a variety of materials for its extensive range of drainage products for all aspects of building and construction.

ACO USA is a sales and marketing company with its own strong manufacturing bases. ACO USA supports its business with all the elements of a diverse company. In addition to modern manufacturing facilities for its product lines, ACO offers field support for all aspects of the business - from specification advice to installation expertise. ACO is the recognized CES provider for architeths and engineers on surface drainage education.

As a market leader, ACO USA is constantly innovating to bring new products to the market. ACO has a fully established R&D department responsible for continuous development, quality, and testing to ensure ACO products continue to lead the market.

During the 1970's, ACO introduced modular, polymer concrete trench drains to the US market. Today, ACO manufactures a range of drainage and landscape products from polymer concrete, stainless steel, mild steel, cast iron, fiberglass, and molded plastics. These diverse material types are used to produce components for all applications - commercial and residential construction, as well as electromechanical engineering and environmental protection.

The ACO Group

ACO USA is part of the ACO Group, a multinational company specializing in products for the construction and building industries.

The ACO Group employs more than 5,000 people worldwide in 40 countries, with production facilities in North America, Europe, China, and Australia, specializing in the manufacture of polymer concrete, cast iron foundry, and plastic extrusion. These resources, supplemented with a worldwide network of agents, make ACO products available in every corner of the world.

The ACO Group is dedicated to achieving the highest possible standards of quality throughout the organization, many companies have either been assessed to or operate an ISO 9002 system, the internationally recognized standard for quality. For full details go to www.aco.com.

Join us at tradeshows to speak with our experts and see our latest products.

Up next:

DHPA (Decorative Plumbing & Hardware Association) Annual Conference - Seattle, WA, November 7-10, 2019

KBIS (Kitchen & Bath Industry Show) - Las Vegas, NV January 21-23, 2020

HDexpo (Hospitality Design Expo) - Las Vegas, NV May 5-7, 2020

AIA Architecture Expo (American Institute of Architects)- Los Angeles, CA, May 14-16, 2020

ASPE (The American Society of Plumbing Engineers) Convention & Expo - New Orleans, LA, September 11-16, 2020

ACO. creating the future of drainage

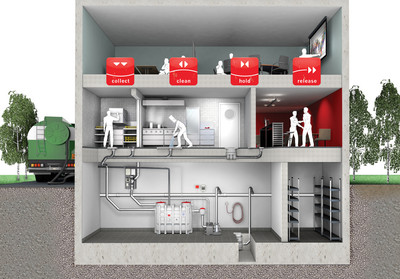

In a food processing and commercial kitchen environment, hot water, grease, and organic waste must be counteracted by more complex and sophisticated drainage concepts. ACO achieves this with intelligent system solutions which optimize food safety of employees and the protection of water. Every ACO product within the ACO system chain safely controls water as it passes along the chain to ensure it can be hygienically, economically, and ecologically handled in a visible way.

System Chain Overview and Benefits

ACO provides solutions which optimize food safety, employee's health and safety, and water protection. Every ACO product safely controls the water to ensure it can be hygienically, economically, and ecologically managed in a viable way.

Food Safety

- ACO Stainless Drainage fulfills hygienic requirements to prevent harmful bacteria contamination. We apply relevant hygienic design principles reserved for food contact surfaces as recommended by EHEDG and NSF/ANSI.

- Our product design ensures minimal buildup of food particles and debris as well as a safe connection with the surrounding floor to minimize any opportunity for bacteria to grow throughout the drain system.

- Slope function and hygienically designed products ensure our system is fully drainable, eliminating the stagnant odor of waste water.

Cost Control

- ACO Drainage Systemscan be easily maintained reducing associated cleaning vosts, thanks to their functional design and cleaning recommendations which have developed in partnership with premium cleaning agent suppliers.

- ACO's advanced manufacturing technologies ensure durability and our special surface treatment guaranteesn corrosion resistance. Our systems perform effectively at all times and keep business disruption to a minimum.

- We provide expertise in drainage system planning, correct installation and creating a safe connection with the surrounding floor to avoid unneccessary costs.

Health & Safety

- Slip resistant grating is used in high risk areas that require heavy water usage providing additional safety.

- Each component of the drainage system is easy to remove and clean, and there are no sharp edges for optimum employee safety.

Material

Stainless Steel

Stainless steel is the name given to a wide range of steels which have the characteristics of greatly enhanced corrosion resistance over conventional mild and low alloy steels. The enhanced corrosion resistance of stainless steel essentially comes from the addition of at least 11% chromium, however, most stainless steels commonly used contain around 18% chromium. Other significant alloying elements include nickel and for superior corrosion resistant properties, molybdenum.

Unique Advantages of Stainless Steel

- High corrosion resistance

- Non-porous, easy to clean and disinfect

- Aesthetically pleasing

- Resistant to extreme temperatures and thermal shock

- Cooefficient of linear expansion similar to that of concrete

- 100% recyclable material

ACO Stainless products are manufactured from austenitic stainless steel, grades AISI 304 or 316L and is ideal for applications including food processing, leisure, dairy, brewing, pharmaceutical, chemical and petrochemical industries.

Surface Treatment

The process cutting, forming, and welding of stainless steel will introduce impurities into the surface of the material and unless the appropriate action is taken, the material will begin to corrode and ultimately fail in service. Therefore, after fabrication, it is vital that stainless steel be treated with the correct surface treatment to ensure it is fully corrosion resistant. By applying pickle passication as the primary surface treatment, the corrosion resistance of stainless steel can be fully restored to its original state, ensuring long and reliable life performance together with the required aesthetic appearance.

Finishes Used by ACO

Pickle Passivation (acid treatment)

All ACO drainage is pickle passivated by immersing products in a series of acid baths. This is a fundamental requirement for removing iron embedded particulates introduced in the fabrication process and also for restoring the chromium depleted regions generated by the welding process. ACO has some of the largest and most advanced pickle passivation installations ensuring optimum corrosion resistance of our products.

Electropolishing (electrochemical process)

After pickle passication, some products are then immersed in an electrolytic fluid in which the products become the anode of a direct current electrical circuit. This process is characterized by a selective attack of the surface of the components whereby upstanding roughness is preferentially dissolved and will yield a progressively smoother, brighter surface. All ACO hygienic trench drain grates are electro-polished.

Brushing (mechanical process)

ACO trench drains have aesthetically pleasing brushed upper edges.

Application

The layout of the drainage system has an impact on future operational effectiveness and costs. This guide offers a range of basic areas which needs to be considered when specifying a drainage system. To specify an appropriate drainage system for a particular application, the zone of operation and amount and frequency of water should be considered.

| Production process/Cleaning Process | High Risk Food Safety Zones | Medium or Low Risk Food Safety Zones | Zones Without Direct Risk for Food Safety |

|---|---|---|---|

| Wet production process/Wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast grates High capacity - high flow rate Slip resistance - high requirement | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow High capacity - high flow rate Slip resistance - high requirement | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. High capacity - high flow rate Slip resistance - high requirement |

| Dry production process/ Wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast iron grates High flow rate Slip resistance - medium requirement | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow High flow rate Slip resistance - medium requirement | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. High flow rate Slip resistance - medium requirement |

| Dry production process/ Controlled wet cleaning process | Full hygienic design - one piece solution without connections; ladder or cast grates Medium to low flow rate Slip resistance recommended | Hygienic design - connections and mesh grates could be considered if cleaning and sanitation procedures allow Medium to low flow rate Slip resistance recommended | Hygienic design is recommended for easy cleaning and maintenance. A combination of products may be considered for easy layout design. Medium to low flow rate Slip resistance recommended |

Type of Drainage

Based on the application, the type of drainage should be selected according to the layout of the operational space and processing technology employed.

Material Resistance

The chemical mixture of the waste water from the process and/or from the cleaning, as well as temperature of the final mixture influences the material resistance of the drainage system.

ACO drainage is manufactured from astenitic stainless steel; grades 304 or 316L according to AISI and is ideal for applications within food processing, dairy, brewery, commercial kitchen, pharmaceutical, chemical, petrochemical, and leisure industries.

Besides stainless steel, drainage products also contain sealing materials:

ACO Floor Drains - All seals are made of NBR (acryl nitrile-butadiene rubber)

ACO Trench and Slot Drains - Flange connection seals are made of NBR (acryl nitrile-butadiene rubber)

ACO Modular Trench and Slot Drains - Flange connection seals are made of NBR (nitrile-butadiene rubber)