Hygiene and Drainage First

Stainless-steel drainage systems are an increasingly popular choice with today’s public-health engineers and designers in the food and beverage, professional kitchen environment, and the pharmaceutical and chemical industries.

Stainless steel offers a host of benefits compared to more traditional materials, including long-term durability and aesthetics. For engineers, the superior hygienic performance, ease of installation, on-site health and safety benefits, and system compatibility with other drainage system components are some of the key advantages.

Due to the lighter weight of stainless steel than other traditional materials, less onsite handling equipment needs to be used, which reduces the risk of a manual handling-related injury. With reduced manual handling required, installation is easier and quicker, reducing installation costs and time.

When looking at the performance of the drainage system once in place, stainless steel also is the material of choice for engineers looking to deliver optimal hygienic performance and lifetime cost efficiency. Stainless steel is easy to clean and its smooth surface helps reduce the likelihood of a drainage system becoming contaminated with harmful micro-organisms and bacteria leading to permanent residence of pathogens within the system.

Ease of cleaning reduces downtime and costs. The high corrosion resistance of stainless steel also means there is no need to apply internal coatings that are expensive and often fail, negatively impacting hygienic performance.

When manufactured to high standards and fully pickle passivated, stainless-steel drain products deliver the advantages of long-term durability, the need for virtually zero maintenance and high life expectancy.

So what are some of the key things a specifier should look for when specifying stainless-steel drainage products?

Clean Products

With industry trends for fresher food choices, less preservatives and less heat treatment, recent research and improvements in best practices tell us the food industry increasingly recognizes poor facility hygiene can be a direct result of bacteria present in a processing facility’s drainage. It’s widely accepted that hygienic drainage is critical to any food manufacturing or processing facility, whether you’re an international brewer or your business manufactures ready meals for a major supermarket.

As a result, the industry needs to incorporate the hygienic design principles usually reserved for food-contact equipment into drainage design and improve specification standards in order to mitigate potential problems.

So why is your drainage specification so important? Apart from the obvious issues regarding public health and brand reputation, there also are regulatory and best-practice standards to consider.

It is clear drainage specification should be a high priority along with the design of the flooring and other infrastructure items.

When specifying hygienic drainage, there are some basic, practical aspects to consider to ensure you have a drainage system that mitigates hygiene risks and the likelihood of cross contamination.

Choosing the right materials: Stainless steel long has been established as the primary material of choice in the food sector and where hygiene is concerned. An engineer or hygienic technologist also needs to consider operating conditions such as acidity and temperature, and more importantly to fully understand the cleaning methodology and chemicals that will be used during the cleaning process before deciding which grade of steel to use.

Welding process: The manufacturing process with regard to welds and welding should include welds that are continuous, smooth, ground and/or polished to eliminate uneven surfaces or pitting. Overlapping joints must not be used, which would create a void that will harbor bacteria. Welds should not be made in corners. Smooth contours eliminate crevices that can harbor bacteria.

Pickle passivation: If it’s not fully pickle passivated, the stainless steel will suffer from corrosion and pitting which, in turn, will lead to the risk that it can’t be properly cleaned. It’s essential that the drainage system is fully pickle passivated. Processors which use localized pickling or pickle paste run the risk of failing to meet longer-term durability requirements.

Product design considerations: This affects both the functionality of the drainage and its “cleanability,” a potentially overlooked consideration in the product selection process.

Designing with cleanability in mind

After taking into account the considerations above, there are four questions you should ask yourself to ensure your drainage system design meets hygienic requirements.

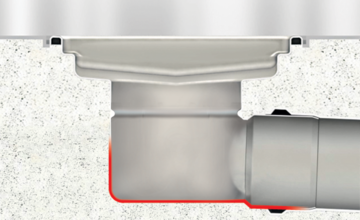

Is your design fully drainable? Drainage channels need to have completely drainable bodies with engineered positive drainage features to prevent the build-up of stagnant water, smells, microbial growth and potential chemical hazards. If the drainage isn’t fully drainable, its hygienic performance will be compromised.

Does your drainage have rounded corners? Sharp corners are harder to clean, particularly if they are situated at a right angle or bend, which means there’s a very real risk that the corner won’t get cleaned effectively. To ensure every part of the drainage surface is easily accessible, drainage should have rounded component features and corners with a minimum radius of 3 mm.

Can your drainage be cleaned without power-washing? In spite of what some companies will say, one of the worst things you can do is power-wash your drainage. Power-washing creates ballistic droplets or a high-velocity spray. Your drainage should be designed in a way that power-washing is not required.

Operational considerations

Health, safety and cost management are keys to running a successful business. Ensure drainage design optimizes the safety of the people working in and cleaning a facility. Some basic requirements include the specification of slip-resistant products and grates that are easy to handle to avoid injuries and cuts.

In terms of cost, ask how cost efficient the drainage system will be in the long term? Is it easy to clean, reducing labor costs and downtime? This reduces the risk of drains being a source of contamination, thereby mitigating risk. Is it durable so it requires the minimum amount of maintenance? How easy is it to work with on a daily basis? Asking these questions during the design stage saves valuable time and money down the road.

After these considerations, rest assured you will have chosen to put drainage first and, as a result, hygiene first.

Other Articles You May Like:

ACO Celebrates Grand Opening of New Facility

Optimizing Hygienic Performance with Drainage Design - Part I

Optimizing Hygienic Performance with Drainage Design - Part II

Hygienic Drain Designs, sanitizers and drain management